- Friday, 28 November 2025

Rising chhena demand boon for DDC

By Shashidhar Parajuli,Biratnagar, Nov. 28:The government-owned Dairy Development Corporation (DDC), which has been facing a market shortage, has begun to feel some relief after the export of the dairy-based dog chew (chhurpi) from Koshi Province increased.

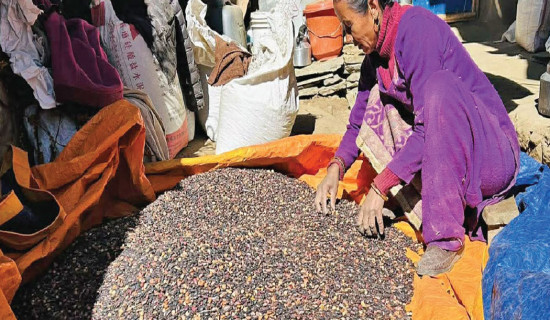

To meet the growing demand for chhurpi, Manram Himalayan Handicraft Pvt. Ltd., a leading private-sector exporter, has started purchasing chhena (a product made by curdling milk) in large quantities from the DDC, benefiting both sides.

The DDC had been losing market share and struggling to sell milk. Meanwhile, Manram Himalayan is now purchasing 25,000 kg of chhena monthly from the DDC's Biratnagar Milk Supply Scheme.

According to Hira Bahadur Magar, Acting Chief of DDC Biratnagar Milk Supply Scheme, the corporation has experienced great relief as private industry has started buying chhena.

“When milk was not sold in the market, we were forced to make milk powder, which is expensive,” Magar said. “Now, we have started making chhena and selling it directly, we only need to operate the powder plant occasionally. This has reduced our processing costs and minimised stockpiling.”

According to Rajendra Kumar Shrestha, owner of Manram Himalayan Handicraft Pvt. Ltd., getting ready-made chhena from the DDC has saved the company both the hassle and cost of collecting milk and processing it into chhena.

Manram Himalayan Handicraft has been producing and collecting chhurpi from Koshi Province and exporting it to the United States.

The business, which began in 2007 by sending just 4 kg of chhurpi to the US as a sample, has now grown into one of Koshi Province’s notable export ventures.

“We initially exported 4 kg, and in 2010, we were able to export a container of chhurpi for the first time,” Shrestha said. “Since then, we haven’t had to look back and are now exporting containers regularly.”

Currently, the company exports an average of 100,000 to 125,000 kg of chhurpi per month through the US-based ‘Himalayan Trade’.

According to Shrestha, up to 150,000 kg of chhurpi is collected per month during peak season.

The industry, which has the capacity to produce chhurpi from 60,000 litres of milk per day, is currently processing about 20,000 litres daily.

To meet the rising demand, the company also operates its own farmhouse in Jhapa, which has 160 hybrid cows that produce around 1,000 litres of milk daily.

“It is not possible to produce such a large quantity alone,” Shrestha said. “That is why we collect milk from areas including Damak in Jhapa and purchase chhurpi produced by farmers in Panchthar, Taplejung, Ilam, and Sankhuwasabha through our collectors.”

Businesspeople claim that the issue of “milk holidays” in eastern Nepal has almost ended after the private sector expanded the chhurpi export market aggressively.

Shrestha said that chhurpi exports have supported the rural economy and ensured fair milk prices for farmers.

Although Nepali chhurpi has high demand in the US, it has yet to enter the European market. The strict standards of the European Union and appears of foot-and-mouth disease in Nepal’s livestock have been major obstacles.

“Europe will not buy dairy products until there is an international lab testing report and certification that Nepali animals are free from foot-and-mouth disease,” Shrestha said.

“The government has launched a vaccination programme to declare Ilam and Jhapa as foot-and-mouth disease-free zones. But had the certification process been faster, our market could have expanded much further.”

He said they expect policy-level facilitation, quarantine support, and easy lab-testing services from the government rather than financial assistance.