Adopt Clean Tech

The brick kilns based on the traditional technology have already proven to be hazardous to the environment as well as human health. Since such obsolete technology uses the substandard coals for fuels, the outmoded kilns are responsible for increasing air pollution and putting the inhabitants’ heath at risk. Numerous studies have shown that the emissions coming out from brick kilns is so deadly that it leads to hundreds of premature deaths besides causing thousands of others to disabilities annually. According to a study conducted under World Bank's regional initiative, the discharge from the brick kilns was responsible for 600 premature deaths and 4,800 Disability Adjusted Life Years (DALYs) in 2015.

This form of pollution is estimated to have US$ 46 million worth of economic cost on public health. With many such kilns are in operation in the Kathmandu Valley, especially in Bhaktapur, they are one of the major contributors to the valley's alarming level of air pollution. This calls for replacing the traditional brick technology with more environment-friendly one. Environmental experts say that the Movable and Fixed Chimney Bull's Trench Kiln (FCBTKs) was the most common design until some years ago. And the brick factories based on this design would emit a lot of hazardous air pollutants. The devastating 2015 earthquake damaged about one-third of the total brick kilns in the valley, causing huge loss to the brick kiln operators.

But the devastation has offered an opportunity for them to rebuild better kilns using improved technology. With this, the brick kilns in the valley have undergone significant positive changes as the rebuilding task was undertaken by the International Centre for Integrated Mountain Development (ICIMOD), together with the Federation of Nepal Brick Industries, MinErgy, GreenTech, and Climate and Clean Air Coalition (CCAC). That initiative deserves credit for such remarkable transformation in the brick kiln industry. As per news report carried by this daily on Sunday, the initiative was responsible for converting some 289 of the 1,035 FCBTKs to zigzag technology. That effort helped reduce 1,134 tonnes of dust particles, with annual savings of 19,986 tonnes of coal valued at Rs. 539 million.

The Industrial Promotion Board had put a ban on the outmoded Bulls Trench technology some 18 years back after the locals of Bhaktapur staged protests against the increasing air pollution due to the brick kilns. After banning that technology, the levels of air pollution in Bhaktapur is believed to have fallen by about 24 per cent. It was the private sector that mostly initiated the aforesaid conversion to zigzag technology after the earthquake. However, the country still has an uphill task to upgrade some 1,600 brick kilns. However, officials at the Ministry of Industry, Commerce and Supplies say that the policy governing the brick kilns is linked with other policies and laws. Brick supply for some 95 per cent of construction works in the country is covered by brick kilns. This is a testimony to the fact that brick kilns play an important role in the construction sector.

Recent News

Do not make expressions casting dout on election: EC

14 Apr, 2022

CM Bhatta says may New Year 2079 BS inspire positive thinking

14 Apr, 2022

Three new cases, 44 recoveries in 24 hours

14 Apr, 2022

689 climbers of 84 teams so far acquire permits for climbing various peaks this spring season

14 Apr, 2022

How the rising cost of living crisis is impacting Nepal

14 Apr, 2022

US military confirms an interstellar meteor collided with Earth

14 Apr, 2022

Valneva Covid vaccine approved for use in UK

14 Apr, 2022

Chair Prachanda highlights need of unity among Maoist, Communist forces

14 Apr, 2022

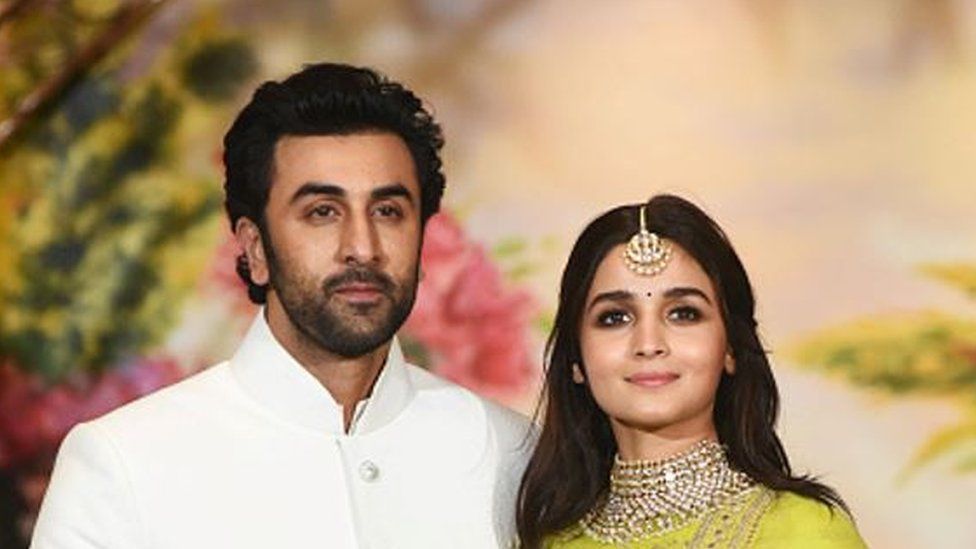

Ranbir Kapoor and Alia Bhatt: Bollywood toasts star couple on wedding

14 Apr, 2022

President Bhandari confers decorations (Photo Feature)

14 Apr, 2022